2024 Benchmark Report Revealing the secrets to best-in-class performance in B2B order fulfillment

Operational insights from leaders at 898 manufacturers and wholesale distributors

Introduction

When it comes to order fulfillment, the best companies can't be satisfied with "good enough" results. Regardless of economic conditions, orders continue to flow, and customers continue to expect top-tier service. Companies need to invest in best-in-class moats wherever they can, especially around any process that makes it easier for customers to keep coming back. To stay ahead of the competition and meet the demands of customers, companies must constantly strive for excellence in their fulfillment processes. This means implementing efficient systems, using advanced technology, and constantly evaluating and improving their operations. In this report, we'll reveal the secrets to successful order fulfillment and how best-in-class companies maintain excellence in this critical aspect of their business.

We partnered with a third party to study order fulfillment in top-performing companies. This report is developed from the responses of 898 manufacturing and distribution executives, responsible for sales, digital transformation, customer success, and other relevant areas.

Survey Participants

0

%

Customer Service

0

%

Sales

0

%

Operations

0

%

IT

0

%

Digital Transformation

What makes order fulfillment such a challenging process?

A painful process can make it hard to recognize opportunities for improvement. The companies we surveyed process thousands if not hundreds of thousands of orders every day, making them experts in the particular challenges of order fulfillment at scale.

22% said cost management

Managing costs is a constant struggle for businesses, and order fulfillment is no exception. High costs of materials and labor, along with the need to balance profitability with other expenses, pose significant challenges.

Effectively managing financial resources to ensure smooth order fulfillment can be a complex task.

18% said supply chain and logistics complexities

The modern supply chain is intricate and interconnected, involving multiple logistics partners and complex supply networks.

This complexity often leads to challenges in coordinating and optimizing the movement of goods, increasing supply chain transparency, and managing relationships with logistics partners.

16% said customer demand and expectations

Meeting customer demands and expectations is crucial for maintaining a competitive edge. However, it can be challenging to handle specific client requirements, manage customer expectations, and fulfill personalized orders.

Failure to meet these demands can result in dissatisfied customers and potential loss of business.

14% said workforce and skill-related issues

A skilled and efficient workforce is essential for smooth order fulfillment. However, finding and keeping skilled labor can be a significant challenge. Workforce management, including training, scheduling, and maintaining employee morale, is crucial for optimal performance and productivity.

10% said technology and system limitations

In today's digital age, technology plays a vital role in order fulfillment. However, businesses often face limitations in their existing technology infrastructure. Missing ERP features, EDI limitations, and slow technology adoption can make order fulfillment slower and less effective.

Most important goals to manufacturing and distribution executives

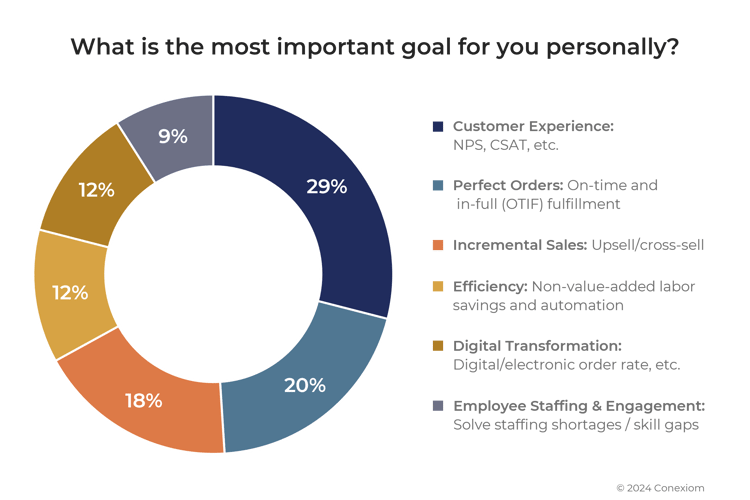

39% of manufacturing and distribution leaders say Customer Experience (CX) is their top priority

Digital commerce has conditioned B2B buyers to want fast and accurate service in all areas of life, including work. Keeping pace with those expectations, not to mention exceeding them, is now an ever-present concern for businesses in competitive markets.

Another 20% of manufacturing and distribution leaders say their top priority is perfect orders

It's not surprising then that Customer Experience (CX) and Perfect Orders were the two most important goals for the manufacturing and distribution leaders we surveyed.

Regardless of economic trends, leaders know reliable growth starts with the customers you keep and the reputation you build from being a reliable partner.

Even though factors like digital experience and maximizing efficiency are less important goals, they still support the larger goal of having a positive customer experience.

If businesses solve for what they can control, such as smooth order processing and seamless fulfillment, then a positive customer experience will likely follow.

Perfect orders help your customers ignore your competitors

According to a past study by Indian River, 10% of customers are in danger of switching to a competitor every year. Failure to consistently deliver perfect orders is the top driver of customer churn.

Businesses that invest in CX and increasing perfect orders position themselves as heroes to customers who can't tolerate recurring, incomplete, or delayed orders.

But before you can be that hero, you have to be sure you aren't the villain.

There is a real gap in how businesses grade themselves vs. how their customers perceive them.

According to a study from Stellar Elements, 81% of businesses believe they meet customer expectations while only 20% of consumers agreed.

Furthermore, 58% of customers thought that the service gap was widening while only 35% of business leaders thought the same. Clearly, there is work to be done to make consumers happier with the businesses they engage.

For many businesses, the customer experience IS the reason for their success. Shortchanging it for a short-term benefit is short-sighted, especially when those customers are being driven to maximize efficiency themselves. Most businesses agree that a positive customer experience is key to growth and revenue generation, but not all of them are critically evaluating their process and partners to ensure they can meet their customer demands now and in the future.

If CX is the most important goal for the leaders we surveyed, it's natural that perfect orders would follow as the second most important. A good customer experience, one that stands a chance of exceeding expectations, starts with increasing your perfect order rate. Maintaining this KPI is a good way to avoid losing customers. But increasing your perfect order rate is how you become a beacon for customers looking for a reliable best-in-class experience.

Why most companies can't deliver more perfect orders

A perfect order is one that meets all customer expectations without any errors, from start to finish. It's delivered on time, complete, and in excellent condition. Think of it as a flawless relay race, where every step in the delivery process is executed perfectly, except the baton is a pallet of fasteners.

This is the standard formula businesses use to calculate their perfect order rates:

.jpg?width=740&height=275&name=Group%201063%20(3).jpg)

Speed and accuracy are the two fundamental pillars of perfect orders. If your deliveries aren't on time or they aren't in full, your promise to customers is broken.

While meeting these expectations is largely dependent on your order fulfillment processes, our research also found what you sell and to whom should inform the technology and expectations behind those processes.

Some customers make it easy to deliver perfect orders (some don't)

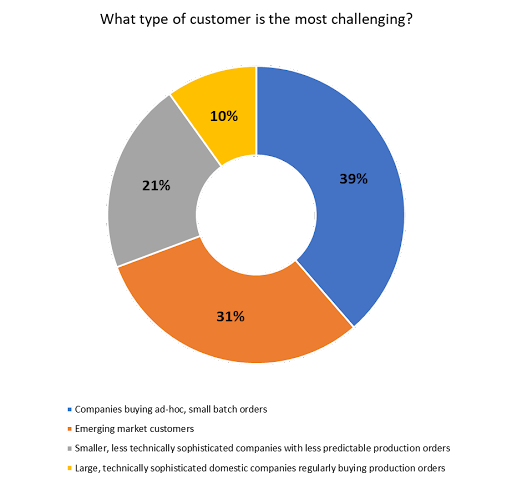

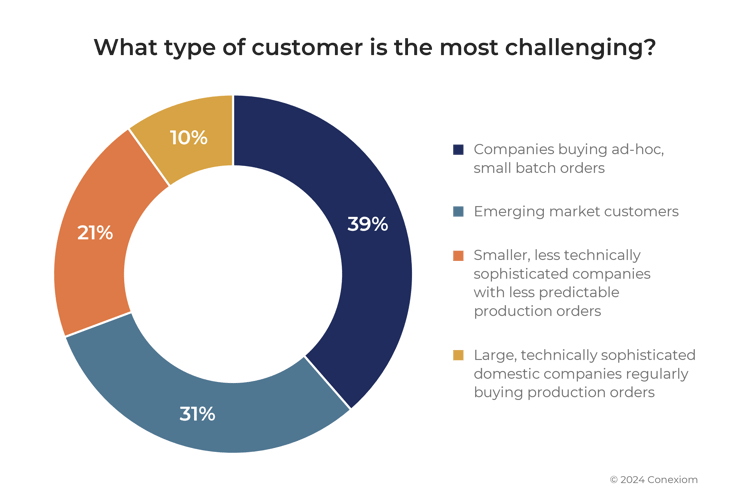

10% of manufacturers and distributors say large, technically sophisticated domestic companies that regularly place orders are the easiest customers.

Larger customers often have the necessary knowledge and resources to navigate the procurement process efficiently, making it easier for manufacturers and distributors to meet their needs. Unfortunately, there are only so many large customers to go around.

21% of manufacturers and distributors say smaller, less technically sophisticated companies with less predictable production orders are the second-easiest customers.

This finding highlights the importance of providing support and guidance to smaller, less technically sophisticated companies. By offering personalized support and clear communication channels, manufacturers and distributors can build trust and loyalty with these customers.

Also noteworthy: Distributors are 5% more likely to struggle serving smaller, less technically sophisticated customers than Manufacturers.

39% of manufacturers and distributors say customers that place small orders inconsistently are the hardest customers to serve

By a wide margin, businesses say they are least equipped to handle orders from companies that buy ad-hoc, small batch orders and emerging market customers. These newer customers may make unpredictable orders not based on any history of prior demand. They also represent a growth opportunity.

31% of manufacturers and distributors say emerging markets are the second-hardest customers to serve

While increasing share of domestic markets is an ongoing effort, emerging markets present growth opportunities that are only projected to rise in coming years. Unfortunately, they're also some of the hardest customers to serve, especially as businesses in these markets lag in adopting technologies like EDI.

Your approach to order processing determines how often you deliver perfect ones

Digital orders are on time 28% more often than manual orders.

Customers want orders to arrive on time and in full. Certain approaches to order processing, like EDI, increase the likelihood of meeting customer expectations while other approaches, like manual order processing, decrease those odds. But there's room for improvement on all fronts.

Which order processing method delivers more on-time orders?

Digital orders like EDI have a significant impact on helping companies streamline their order fulfillment processes.

Businesses that use EDI are much more likely to say that at least 90% of their orders are fulfilled on time compared to those that use manual order processes.

There’s still a big gap to fill. Over half of respondents using EDI systems say that less than 90% of orders they process are on time. EDI can also only go so far in reducing this gap further. The amount of partner alignment, resource investment, and error mitigation necessary to maintain EDI systems means that the rate of EDI adoption reaches a natural plateau.

Only 2% of companies reported on-time rates over 95% from manually processed orders

On the other hand, manual order processing is the worst offender. Almost no companies that use manual processing say that at least 95% of their orders are fulfilled on time. 70% say that number is less than 90%.

When you factor in cut-off times for same-day shipments, manual order processing can delay orders up to two days.

Which order processing method creates more order errors?

But what about those instances where EDI cannot be used? Almost 1/3 of respondents said that 10% of their manual orders or more contained errors. Only 1/3rd of respondents could keep their error rates under 5%. As Conexiom data reveals, manufacturers are better at eliminating errors before they have an impact, but distributors are better at fulfilling orders on time.

This tradeoff should not exist. Manual processing forces suppliers to either delay orders to check for accuracy or have them ship quickly and accept a high level of error as a result. Neither provides a positive customer experience. But this dilemma is ultimately a false one. The tradeoff can be eliminated by the judicious application of automation to transfer incoming order information into your ERP, even in the absence of EDI.

How to save thousands by improving one order fulfillment KPI

Order errors can significantly affect your business, with three primary consequences being customer churn, returns, and restocking, and the need for corrections before shipping. Combined, these issues account for nearly 75% of the most substantial impacts stemming from mistakes in order processing.

According to past research, 32% of your customers will leave after one bad experience, while getting a new customer is nearly five times more expensive than keeping a current one.

34% of manufacturers and distributors say the cost of order errors is most affected by customer churn

Since a good customer experience is a top goal for many companies, order errors, particularly those that occur due to manual processing, are to be avoided at all costs.

he significant repercussions of returns and pre-shipping corrections stem from businesses striving to meet customer satisfaction. With the customer experience reigning supreme, order errors pose a genuine danger to those seeking to enhance their business operations.

The error rate for manual orders is 200% higher than for digital orders

Effective solutions for reducing order errors are seamless, require minimal customer effort, and enable transparent communication with customers.

$17,800 is the average, total cost per order error

Over 70% of individual order errors cost at least thousands of dollars. This fundamental problem requires dedicated resources to solve. Ideally, these errors would be caught in 5 minutes before they ever get processed in the first place. This means more investment in either workforce or technology if companies want to avoid errors.

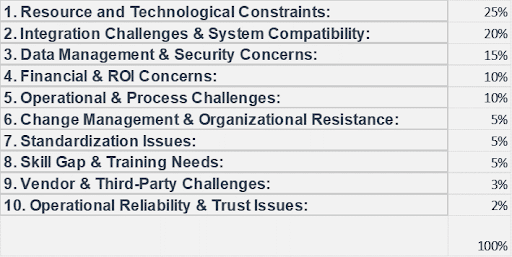

Barriers to Good Order Fulfillment

Resource and Time Management

Distributors and manufacturers are constantly asked to do more with less. Expect this to become only more important as demand rises for more diverse and personalized orders. Managing full-time employees’ time effectively has always been crucial to the success of any business, but this is especially true now as the search for efficiency continues into an expected growth period.

Customer Experience

Long-term customer satisfaction is of the utmost importance. Yet it is also among the most difficult to achieve. an extensive list of every aspect of a vendor’s performance including order fulfillment all feed into the overall customer experience. Seemingly small issues become large when they cause unhappy customers to look elsewhere to fulfill their needs. In particular, consistent communication and follow-up can be difficult, especially when a business has a large number of partners.

Electronic Data Interchange (EDI)

EDI is the gold standard for order processing as its automated approach automates many orders. According to Epicor, the ERP market grew 12.3% in 2022. The need for EDI to service this growing market is rising as well, yet the burden it places on supplier-customer alignment means that 100% adoption will never be possible. There are gaps with this approach. Errors can slip through the order process and create downstream headaches in fulfillment. This is especially true for suppliers with many midsize or smaller customers.

Automation

Ill-fitting automation can be more trouble than it’s worth. Periodic updating, uncaught errors, and the need to accommodate unrecognized templates means that employees can spend more time fixing issues and double-checking results than they would if they were to process a task manually, ultimately counteracting the industry’s search for productivity gains.

Learn how well you perform against your peers on these KPIs

Schedule a call with one of our order fulfillment experts to review benchmark data tailored to your company's industry, vertical, product catalog, and annual revenue.

What's keeping your customer service team from serving customers?

CSRs spend nearly 50% of their on repetitive work

Employee time is split remarkably evenly between the four tasks of troubleshooting order fulfillment, recommending the right products to customers, communicating order updates, and data entry.

This is remarkably inefficient. The latter two activities comprise almost 50% of a team’s time, even though they are tasks that are ripe for automation. If these tasks can be eliminated, employees gain more time back to interact positively with customers and solve meatier issues.

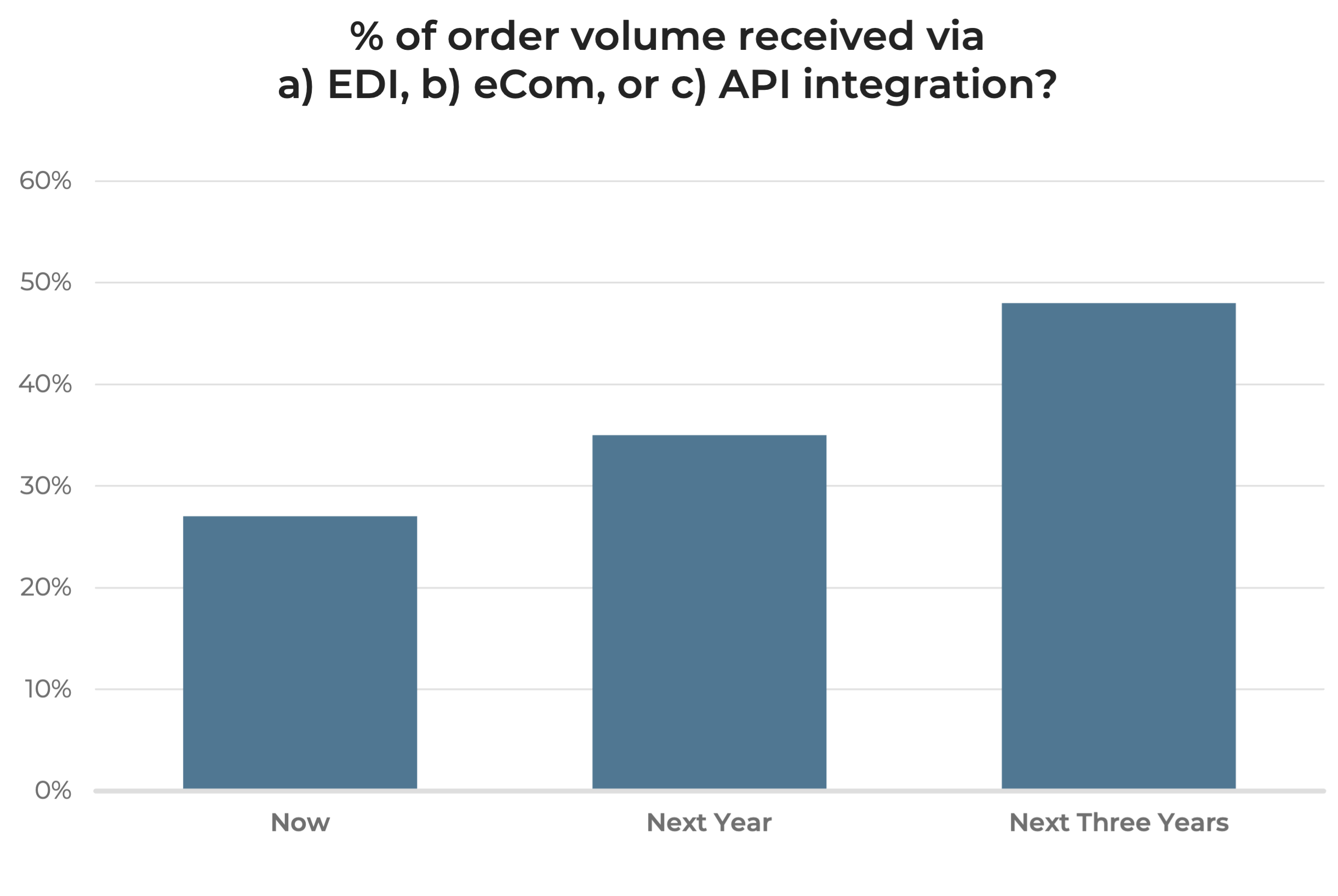

Why manufacturers and distributors are spending more to close the digital order gap

Consistently, across organizations of all sizes and types, businesses are willing to spend about 10% more than they currently shell out if it meant they could acquire the ideal order processing system. The fact that there is a gap this large and consistent points to a real need within the industry that suppliers will spend to fix if the opportunity arises.

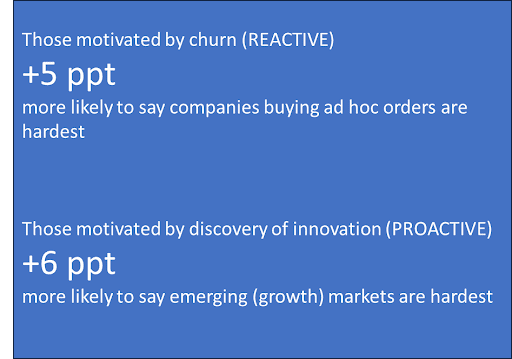

Companies that are motivated to adapt innovative technologies because they are taking recommendations from consultants or because they are missing performance metrics have an even higher gap as they recognize primarily that this is a problem that needs to be solved.

Those that solve this first will have an edge over their competitors.

Why companies will spend 10% more to optimize order processing

-

38% of respondents say that a performance miss on key metrics drives investments in order processing optimization.

-

24% of respondents say that a top-down initiative drives investments in order processing optimization.

-

18% of respondents say discovering a new and useful innovation drives investments in order processing optimization.

-

10% of respondents say that an existing IT initiative (e.g., ERP upgrade) drives investment in order processing optimization.

-

7% of respondents say that a recommendation from a consultant or trusted advisor drives investment in order processing optimization.

-

4% of respondents say that a major customer churning or reducing spend drives investment in order processing optimization.

Top three strategic reasons businesses plan to invest in order processing solutions that drive increased profits and customer satisfaction:

1. Actionable Data

2. Customer Relationships

3. Strategic Planning

Automated order processing can give businesses the data they need to improve their business while allowing them to communicate with their customers seamlessly. There is less room for error and uncertainty, ultimately boosting customer satisfaction.

9 Secrets of Best-in-Class B2B Order Fulfillment

-

Customer experience informs every step in the process.

-

Enables profitable growth regardless of order frequency, volume, and channel.

-

Tailored order processing to fit their product offerings.

-

Always revealing opportunities to increase perfect orders.

- Improves order fulfillment processes without waiting for customer churn.

-

Increases profits by tracking orders error sources and costs holistically.

-

Provides a competitive edge regardless of economic trends.

-

Ensures customer communication is proactive, frequent, and solution-oriented.

-

Closes the digital gap.

Final thoughts

Five steps businesses can take today

-

Adapt flexible processes and modern technologies that can accommodate growing but unpredictable demand.

-

Improve the customer experience with automation that fits their formatting and ways of working.

-

Focus on QA to ensure accurate document processing and avoid downstream problems like returns, incorrect shipments, and invalid orders.

-

Adopt an integrated approach to automation as manual order processing is incompatible with the growth goals and seamless customer experiences that modern businesses must pursue.

-

Invest in solutions now as peers are already looking to upgrade their technology vendors in an expected growth market.

And there are more insights to reveal..

-

What is the digital adoption gap for companies?

-

Why do companies invest in new technologies?

-

What are companies’ priorities and trusted sources of information?

-

Stay tuned for our guide to closing the digital order gap.